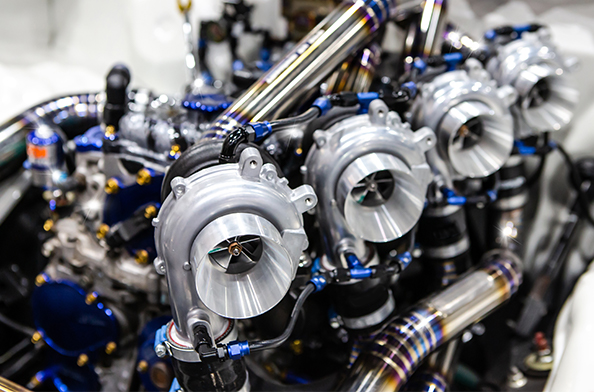

AUTOMOTIVE LEAK DETECTION EQUIPMENT

ATEQ provides a variety of instrument for flow analysis and supplies automotive leak detection equipment. We have many Tier 1 suppliers that utilize our testers to confirm that the parts supplied to their OEM (Original Equipment Manufacturers) clients meet their specifications.

The guidelines they receive will include the acceptable variances for the size of the components, and also the allowable leak tolerances and flow capacity. Our testing is done with clean, dry air provided through on-site compressors or bottled nitrogen. Depending on the tolerances required, ATEQ also has testing products that work with hydrogen.

These testers offer a higher degree of sensitivity when required.

The OEMs also utilize ATEQ products in a number of ways. They will perform component testing to confirm that parts received meet the requirements of the contract. Many OEMs cast their own primary components, and will want to test them to confirm these pieces are functioning as designed. The testing performed is done on the individual parts, and then further on the fully assembled product to ensure that the entire system meets the requirements. With ATEQ’s sensitivity and accuracy, manufacturers are able to quickly and accurately identify a leak that exceeds accepted tolerances. ATEQ’s product suite also includes sniffers that enable technicians to quickly identify the source of any leaks, and determine if they can resolve the issue themselves or if the component must be replaced.

The Air Conditioning (AC) system is a good example of where ATEQ’s automotive leak detection equipment can be used. The entire system must remain closed to ensure that the refrigerant remains in the system. Leaking refrigerant can have an environmental impact. Furthermore, if the system operates without adequate refrigerant, a leak can damage the system and require costly repairs. OEMs want to make sure that such systems are performing at their optimum level before leaving the plant, thus limiting exposure from liability and potential for recalls.

ATEQ’s sales team is uniquely qualified to assist you in determining the best product for your testing needs. Each member of our sales team has an engineering background and understands the technical language of the production environment. Contact us today and find out how ATEQ can provide the equipment you need to meet your automotive leak testing goals.

“Ateq is dedicated to your long-term success”

TYPICAL APPLICATIONS FOR AUTOMOTIVE LEAK DETECTION EQUIPMENT

• 4 wheel drive hub locks

• Automotive air conditioning components

• Automotive brake calipers

• Automotive radiators

• Miniature plastic valves

• Exhaust

– Complete

– Quiet

– Catalytic converter

• Transmission housing

– Component and assembly

• Torque converter housing

• Motor

– Intake manifold

– Head

– Block

– Turbo

– Complete set

• Fuel lines

• Brake lines