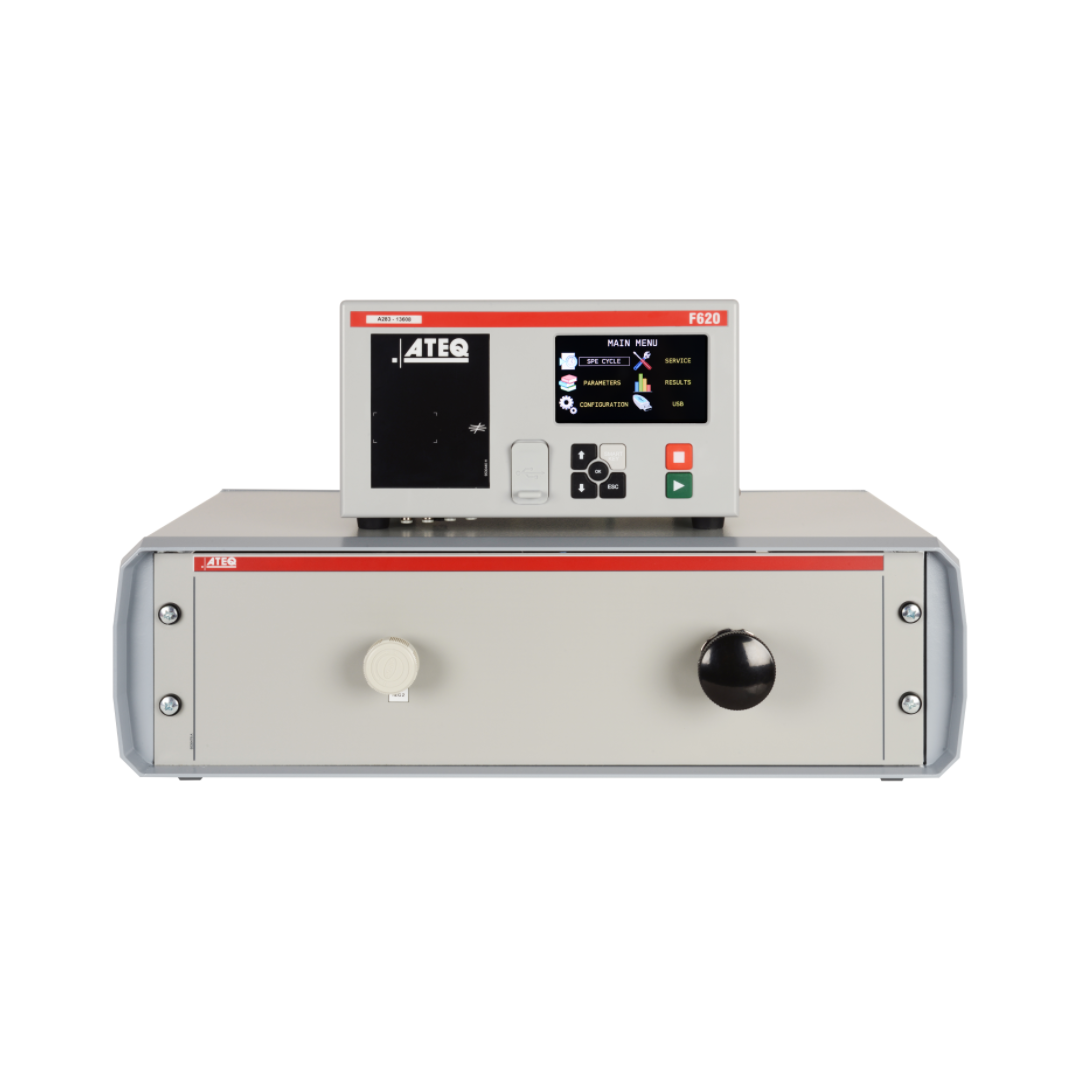

F620LV LARGE VOLUME LEAK TESTER

COMPACT LEAK TESTER FOR LARGE VOLUME

F620LV is a breakthrough instrument able to leak test very large volumes using a new patented technology (Based on Pressure Decay) thanks to the high sensitivity of our latest pressure transducer.

By using ATEQ’s F620 Large Volume Differential Pressure Decay Leak Tester with DNC, it is now possible to detect pressure drops below 0.1 Pa/sec.

F620LV APPLICATIONS

F620LV FEATURES

• 128 programs

• Large Flow Valves for fast management of the parts

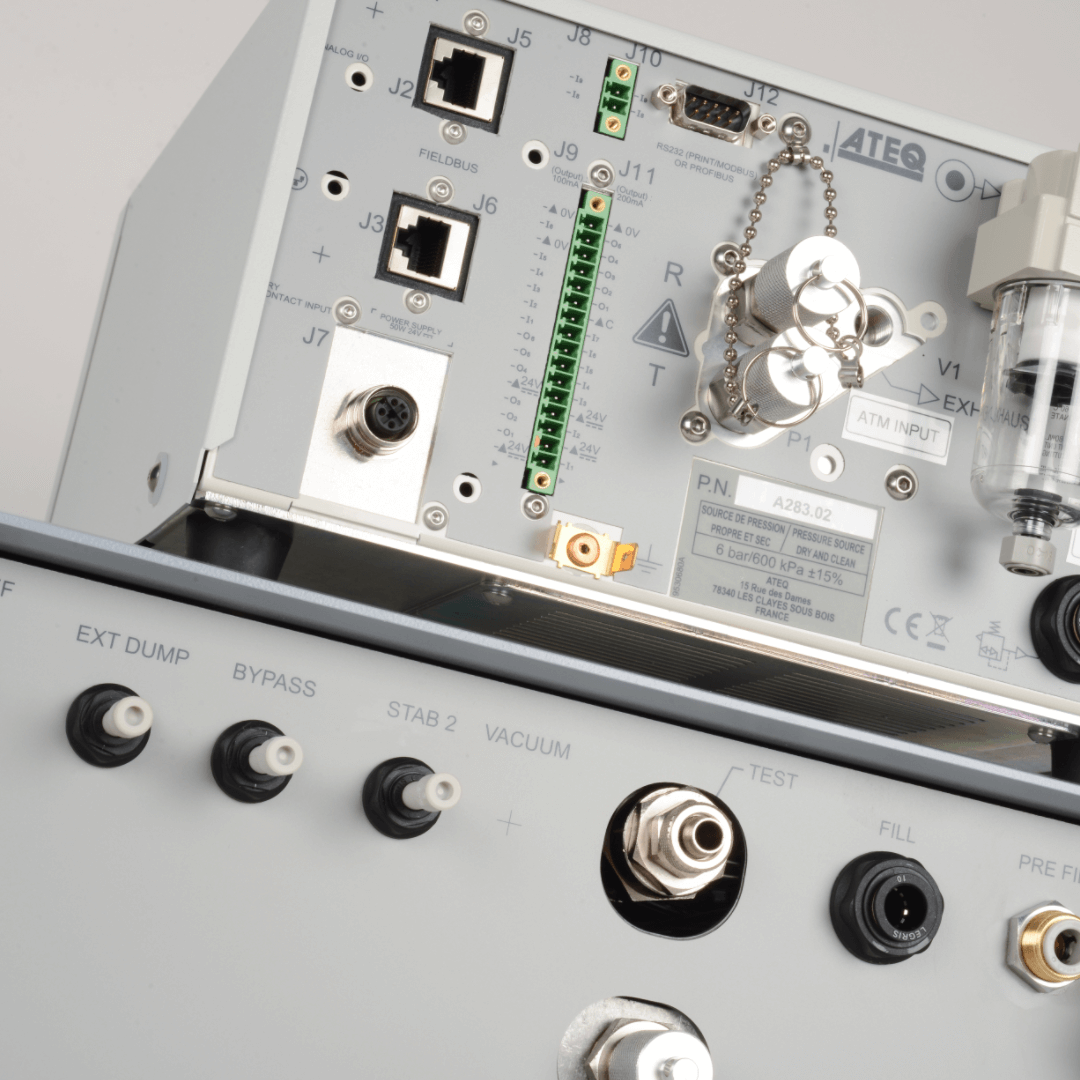

• Fully integrated electronics and pneumatics

• Flexible communication format: RS232, USB

ENVIRONMENT :

ROHS standard

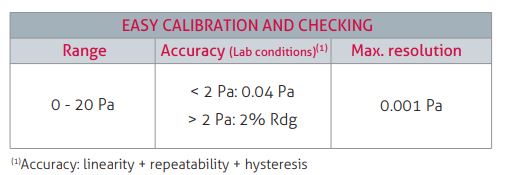

MEASUREMENT CHARACTERISTICS :

| PRESSURE DROP MEASUREMENT |

|---|

MEASUREMENT CHARACTERISTICS :

| Range | Accuracy up to* | Max. Resolution |

|---|---|---|

| 0 – 20 Pa** | < 2 Pa: 0.04 Pa | 0.001 Pa |

| 0 – 20 Pa | > 2 Pa: 2% Rdg | 0.001 Pa |

Accuracy: linearity + repeatability + hysteresis *Optional laboratory accuracy **Maximum Test Pressure 3 bar

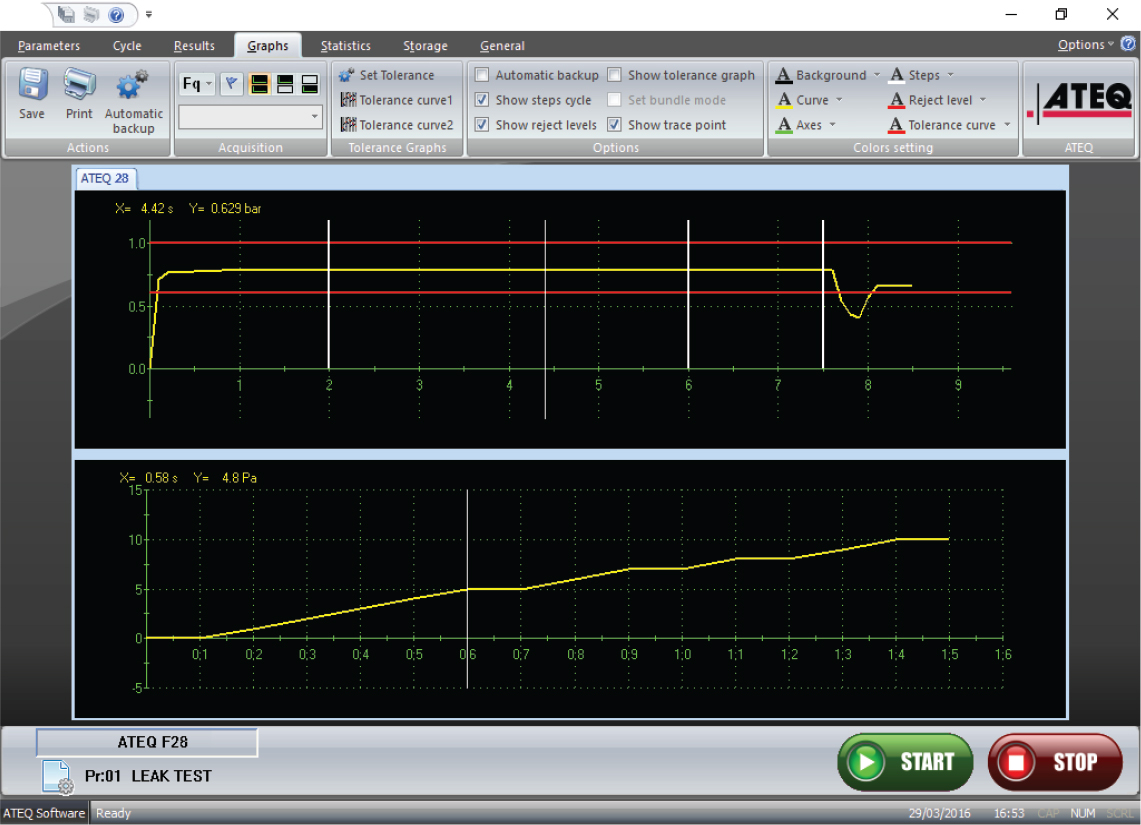

WINATEQ 300 CONTROL INTERFACE

F620LV SPECIFICATIONS

F620LV OPTIONS

- 9 inputs / 5 outputs

- Optional Fieldbus: PROFIBUS, DeviceNet, PROFINET, EtherNet/IP, EtherCAT network, Modbus RTU

- 2 pneumatic outputs for automation

- Clean and dry air required

- Air quality standard to be applied (ISO 8573-1)

F620LV TECHNOLOGY

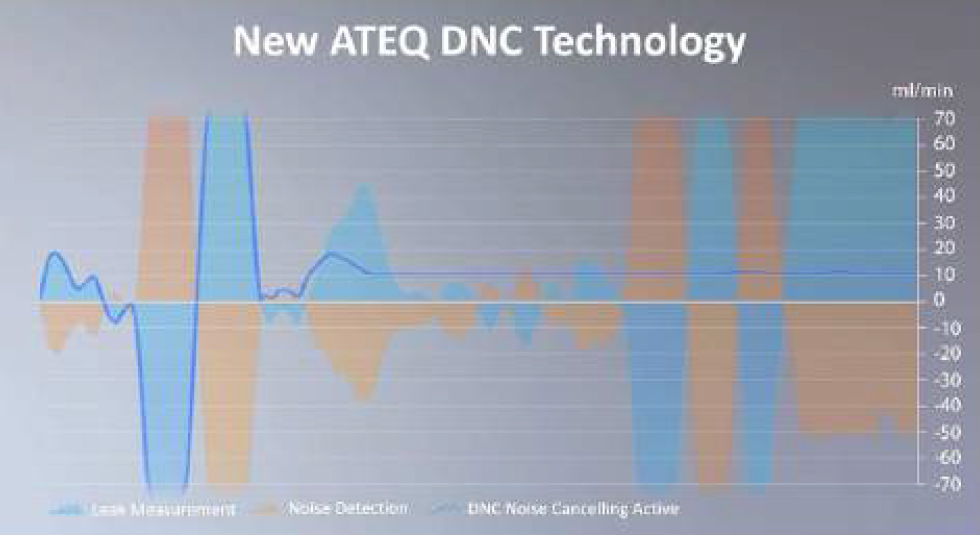

DNC TECHNOLOGY

NEGATE BACKGROUND DISTURBANCES FROM LEAK READINGS

When leak testing a large, flexible component in a ‘noisy’ factory environment, use ATEQ’s new Differential Noise Canceling (DNC) leak testing technology to produce faster, more accurate leak readings that are not influenced by fluctuating background disturbances.

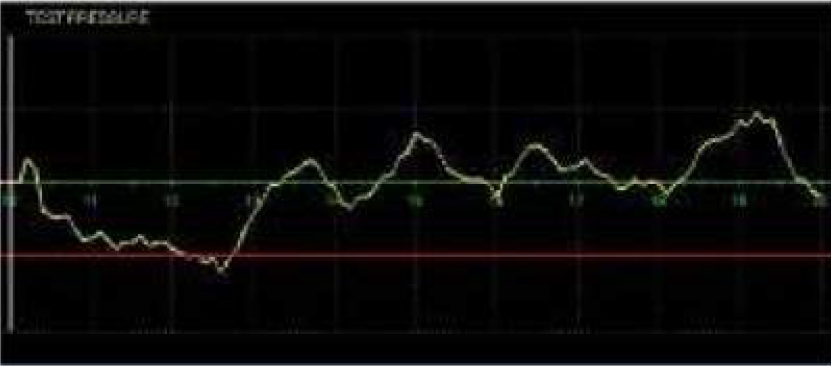

FACTORY DISTURBANCES

- Temperature Variations

- Opening Doors or Windows, Fans, HVAC Systems

- Pressure Variations

- Time of Day, Weather, Sound Level

- Vibrations

- Machine Movement, Wind, Forklifts, Music

ATEQ’s DNC function provides a more stable leak reading by compensating for background disturbances so they don’t influence the leak sensor.

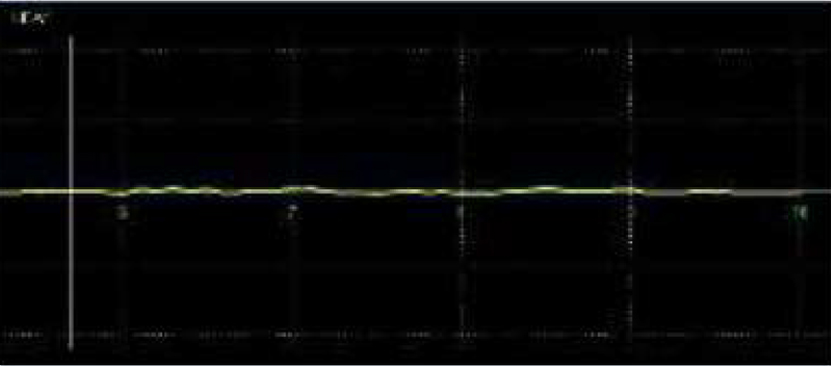

Leak Reading Without DNC

Leak Reading With DNC